Frequently Asked Questions

At ECO₂ Systems LLC, we’re committed to transforming homes with eco-friendly water heaters that deliver exceptional performance while reducing carbon emissions. We specialize in providing innovative solutions like renewable energy water heaters, split system heat pump water heaters, and other energy-efficient water heating systems that support sustainable living. This page is designed to empower you with clear, straightforward answers to your questions about high-efficiency hot water systems, ultra-low carbon water heaters, and more. Whether you're curious about how heat pump water heaters work or need help choosing the right sustainable home water heater for your needs, you’ll find all the information you need right here.

How does a heat pump work?

A heat pump works by using a refrigerant, a special fluid that easily changes between liquid and gas states. It circulates the refrigerant through a closed loop. When in the cooling mode, the refrigerant absorbs heat from the source medium and turns into a gas. The gas is then compressed, which makes it even hotter. This hot gas releases the heat to the destination medium, and as it cools down, it turns back into a liquid. Some refrigerant gases are toxic or have significant global warming potential (GWP) when released into the atmosphere. R744 is a refrigerant (essentially CO₂) that is non-toxic and has the lowest GWP of all refrigerants used today.

What is a heat pump?

A heat pump is a device that moves heat from one medium (such as air or water) to another using a pair of heat exchangers (the condenser and the evaporator). One example is a refrigerator, which uses a heat pump to move heat from the air inside the refrigerator to the air outside it. Another example is a reverse-cycle air conditioner. In the summer, it uses a heat pump to move heat from the air inside your home to the outside. In the winter, the cycle reverses to move heat from the outside air into your home. There is heat present in a medium even if it is below freezing. Ground source (or geothermal) heat pumps extract heat from the earth or water below ground where the temperature is fairly constant throughout the year. A Heat Pump Water Heater uses the same principle, but the first heat exchanger extracts heat from the surrounding air and the second heat exchanger moves heat into a water tank to heat water.

How is a heat pump so much more efficient than a traditional electric water heater?

By extracting and moving heat rather than generating it from scratch, a heat pump can be significantly more energy-efficient than a traditional system that generates heat. This is because it takes less energy to move heat than to create it. A Uniform Energy Factor (UEF) value of 1 would indicate that the Heat Pump Water Heater is 100% efficient, meaning all the input energy is effectively converted into useful heat energy for heating the water. Water heaters that create heat will always have a UEF lower than 1, whereas Heat Pump Water Heaters may have a UEF between 3 and 4 or sometimes even higher, indicating that they are 3 or 4 times as efficient as a resistance electric water heater, for example.

Why does CO₂ as a refrigerant matter?

Heat pumps require a refrigerant gas in order to effect heat transfer. Historically, many of these refrigerants have been toxic, flammable, or harmful to the ozone layer which protects the earth from dangerous UVB radiation from the sun. Ozone-depleting refrigerants are almost completely phased out, but many of the most popular refrigerants such as R-410A and R-134a are greenhouse gases with significant Global Warming Potential (GWP) of 1,000 or 2,000 times that of CO₂. Although these refrigerants are sealed in the heat pump, they do occasionally leak out during manufacture, malfunction, when the heat pump is first “charged” with refrigerant, or at the heat pump’s end of life. CO₂, by contrast, is a naturally occurring gas that is extracted from the environment, has a low GWP of 1, and is eventually returned to the environment from where it came. The operation of a heat pump, when powered with renewable electricity, produces no carbon emissions at all.

What is a Uniform Energy Factor (UEF)?

The Uniform Energy Factor (UEF) is a measurement used to evaluate and compare the energy efficiency of residential water heaters, particularly those that use storage tanks. It is a standardized metric introduced in the United States in 2015 by the U.S. Department of Energy (DOE). The UEF takes into account multiple factors to determine the overall efficiency of a water heater, including standby heat loss, cycling losses, and heat input efficiency. It provides a single numerical value that represents the energy efficiency of a water heater, expressed as a ratio of heat created to energy input. A higher UEF indicates greater energy efficiency, meaning the water heater can heat water more effectively while using less energy. A perfectly efficient traditional gas or electric water heater can have a UEF of at most 1 because it cannot create more heat than the energy it uses. However, Heat Pump Water Heaters do not create heat, they move it from ambient air to the storage tank, and thus they are currently able to achieve UEFs in the 3-4 range or higher.

How do I get a SANCO₂?

Homeowners can purchase a SANCO₂ from a local installer. Consult our directory here, and if you cannot find a local installer, contact us and we will locate one for you.

Installers and design, engineering and construction professionals can order from our network of distributors, which are listed here. If you cannot find a local distributor, contact us and we will locate one for you.

Installers and design, engineering and construction professionals can order from our network of distributors, which are listed here. If you cannot find a local distributor, contact us and we will locate one for you.

Will the SANCO₂ work in cold climates?

Even when the air outside is below freezing, it still contains a significant amount of heat energy. When the compressed refrigerant gas is released through an expansion valve, it cools rapidly. As long as the refrigerant gas is colder than the surrounding air, heat will move from the relatively warmer air through the heat exchanger to the relatively colder refrigerant, which absorbs this heat and allows it to be transferred to the water in a second heat exchanger. Although the efficiency of the system does decrease at very low temperatures, the SANCO₂ is tested and certified to operate in a range of -26°F to 114°F.

Can I install the SANCO₂ heat pump indoors?

The SANCO₂ heat pump unit can be installed anywhere where there is sufficient area (approximately 400 - 800 cu. ft. of space per heat pump, depending on whether the space is ventilated or not) to allow for adequate airflow. When it is running, the unit will provide about 15,400 btu/hr of cooling capacity as it extracts heat from the air. It can be installed in a garage, attic, basement, mechanical room or commercial kitchen, for example.

Which size tank do I need?

The tank size and the number of heat pumps depend on the total hot water usage requirements and on the groundwater temperature. A typical single-family home will require a single heat pump and either a 43 or 83 gallon tank. Refer to our online sizing tool to generate a specific sizing recommendation for your application.

Does the SANCO₂ need to be charged with refrigerant in the field?

No. The SANCO₂ is a self-contained appliance that arrives fully charged with CO₂ and does not require anything other than the plumbing and electrical work to install it. The refrigerant loop is not field serviceable and is covered by our warranty against leakage or failure.

How much will I save in utility charges?

A SANCO₂ will use about 20% of the electricity of a traditional resistance electric storage water heater, resulting in a saving of up to 80%. This is affected by the ambient temperature as the unit works harder to extract heat from very cold air, and efficiency starts to decrease on days below about -5 degrees F. Use our Savings Calculator to look up the electricity, natural gas, oil or propane rates in your area to estimate your utility savings.

Can I install multiple tanks or multiple heat pumps?

Yes. Commercial and multi-family applications routinely deploy multiple heat pumps and multiple tanks. We offer commercial tanks in vertical and horizontal formats up to 505 gallons. An array of heat pumps, installed together with a controller, allows us to scale a system with built-in redundancy for large scale applications.

We also support certain configurations where multiple tanks are installed with a single heat pump, for example where space constraints require it.

We also support certain configurations where multiple tanks are installed with a single heat pump, for example where space constraints require it.

What rebates or other incentives are available?

There are various federal, state, local and utility rebates and incentives available in different areas. Refer to our incentive lookup, or visit Energy Star's rebate finder.

Is the outdoor unit at risk of freeze damage?

The heat pump has a freeze protection feature built in. When the water temperature in the heat pump drops below a certain threshold, the heat pump will turn on to circulate warmer water through the pipes connecting the heat pump to the storage tank. If there is a risk of disruption to the electricity supply, we recommend the addition of our Freeze Protection Valve Kit. These valves will open to drain water from the heat pump and from the plumbing to and from the heat pump in the event that the water temperature drops below a slightly lower threshold, indicating that the heat pump's freeze protection cycle failed to run, for example in the event of a power outage.

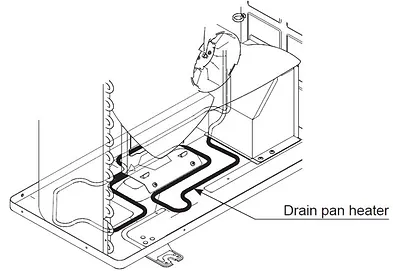

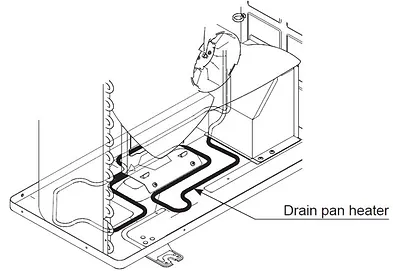

We also recommend the installation of the "-D" model heat pump in cold climates. This model includes a drain pan heater to prevent ice buildup in the condensate drain pan.

Further, we recommend the installation of heat trace tape on the exterior plumbing in colder climates.

We also recommend the installation of the "-D" model heat pump in cold climates. This model includes a drain pan heater to prevent ice buildup in the condensate drain pan.

Further, we recommend the installation of heat trace tape on the exterior plumbing in colder climates.

What is the difference between the standard and the "-D" model?

The GS5-45HPC heat pump is our standard model. With the GS5-45HPC-D model the only difference is the internal addition of an electric element in the drain pan.

All other components are identical, and performance is exactly the same, although below 34F ambient the 132W electric element will turn on, resulting in a small increase in the power draw of the unit. The Dept of Energy's UEF & FHR testing is standardized at 67F ambient for all water heaters, so there is no impact to the official performance data because the heating element does not turn on at the test temperature. The Drain Pan Heater was added because freezing temperatures can lead to ice or frost formation on the evaporator coil. The GS5 unit runs a defrost cycle which melts the ice on the coil. This melted ice can pool in the drain pan, where it could freeze before draining away through the drain elbow. This could potentially cause ice buildup in the drain pan, which could eventually obstruct the fan blade or affect the water pump. The addition of the drain pan heater in the -D model addresses this problem. The -D model is sold in regions where this added freeze protection is necessary.

All other components are identical, and performance is exactly the same, although below 34F ambient the 132W electric element will turn on, resulting in a small increase in the power draw of the unit. The Dept of Energy's UEF & FHR testing is standardized at 67F ambient for all water heaters, so there is no impact to the official performance data because the heating element does not turn on at the test temperature. The Drain Pan Heater was added because freezing temperatures can lead to ice or frost formation on the evaporator coil. The GS5 unit runs a defrost cycle which melts the ice on the coil. This melted ice can pool in the drain pan, where it could freeze before draining away through the drain elbow. This could potentially cause ice buildup in the drain pan, which could eventually obstruct the fan blade or affect the water pump. The addition of the drain pan heater in the -D model addresses this problem. The -D model is sold in regions where this added freeze protection is necessary.