Technology - How It Works

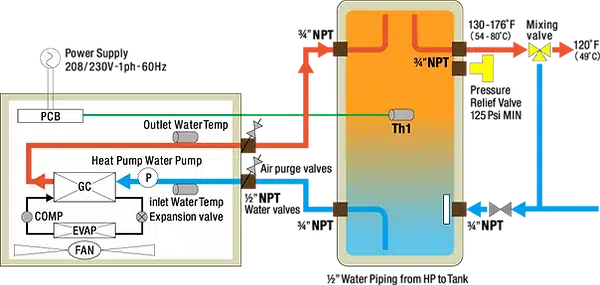

The SANCO₂ water heater works like any other storage water heater with one exception. The tank is stratified rather than mixed.

Cold water connections are located at the bottom of the tank and hot water connections are at the top.

The hot water stored in the tank is hotter than necessary for normal use in the home or building. The unit is supplied with a thermostatic mixing valve that must be installed to temper the delivered water to the unit.

- As hot water is used in the home or building, it is replaced with cold water at the bottom of the tank. This cold water does not mix with the stored hot water. Instead, it pushes the stored hot water towards the top of the tank.

- As more hot water is used and the volume of the cold water increases, the temperature sensed at Th1 (tank temperature sensor) falls. When the temperature at Th1 is below 113°F(45°C), the sensor signals the heat pump to start.

- The water pump in the heat pump operates by pulling the cold water from the bottom of the tank via the ½” water piping between the tank and the heat pump.

- The heat pump compressor starts and heats the water to the set temperature by drawing heat from outside via the CO₂ refrigerant and the double wall heat exchanger.

- The hot water is then returned to the top of the tank for use in the home or building. Returning the heated water directly to the top of the tank reduces tank recovery time.

- Hot water is generated at 145-150°F.

- As the heat pump continues to operate and heat water (unit will heat approx. 22 gallons per hour), the water at the top of the tank replaces the cold water at the bottom of the tank.

- The heat pump ignores the temperature sensed by Th1, but monitors the inlet water temperature (i.e., the temperature of the water at the bottom of the tank). When this inlet water temperature reaches 122°F (50°C), the unit determines that the tank is completely full of hot water and the heat pump shuts down.

- The heat pump then waits until the Th1 tank sensor reads a temperature below 113°F (45°C) before restarting.

The unit has a time clock to allow programming of an On/Off period of use and also a “Dry Contact” to enable the use of a remote On/Off signal from a BMS system or other device.