Energy Efficiency

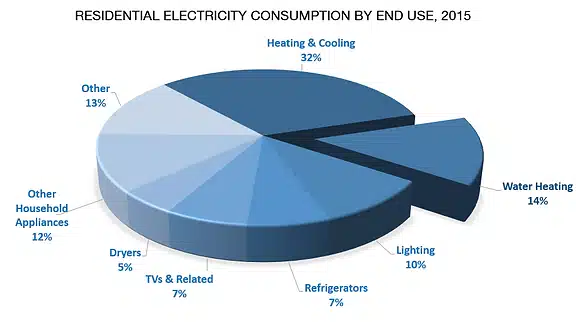

Did you know that water heating is the second largest use of energy after heating or cooling in a typical home? Water heaters also account for a significant fraction of total energy usage in residential and commercial buildings.

The US Department of Energy measures water heater efficiency with a metric called UEF (Uniform Energy Factor).

This is a metric used for all water heaters, measuring the energy used in a 24-hour period with prescribed hot and cold water temperatures, water volume used and recovered, and a specific ambient temperature around the water heater.

Source: U.S. Energy Information Administration, 2015 Residential Energy Consumption Survey

- Natural gas water heaters, both storage and tankless, must have UEF values below 1 as it is impossible when burning natural gas to have 100% of the energy transfer to the water. Some of that energy is lost in the flue gas (a by-product of combustion).

- Electrical resistance water heaters, both storage and tankless, must also have UEF values below 1 as they cannot transfer more energy into the water than is supplied to the electric element. Typically, an electric water heater has a UEF very close to 1, and any deviation is due to standby losses from the hot water in the tank

Heat Pump Water Heaters (HPWH) typically have UEF values above 2.5, because a heat pump extracts heat from the air surrounding it via the refrigerant, and it can thus transfer more heat energy into the water than it consumes.

- Inverter compressor - Inverter compressors increase the efficiency of a heat pump by varying the speed of the compressor and hence the amount of electrical energy used, depending on the ambient temperature at the heat pump (the warmer the air, the less energy is required to extract heat) and the set point and usage load. The SANCO₂ is the only residential HPWH to use an inverter compressor to move the refrigerant.

- DC fan motor & water pump - The other motors in the SANCO₂, the fan and water pump, are also powered by direct current (DC), just like the inverter compressor. This allows both to run at a speed based on load requirements to optimize energy efficiency.

These features allow the SANCO₂ to be extremely energy efficient under all ambient temperatures, resulting in a best-in-class COP (Coefficient of Performance, Power Out / Power In).